xelsius control

The xelsius workstation is operated on a touch screen with the intuitive software xelsius control.

KEY FEATURES

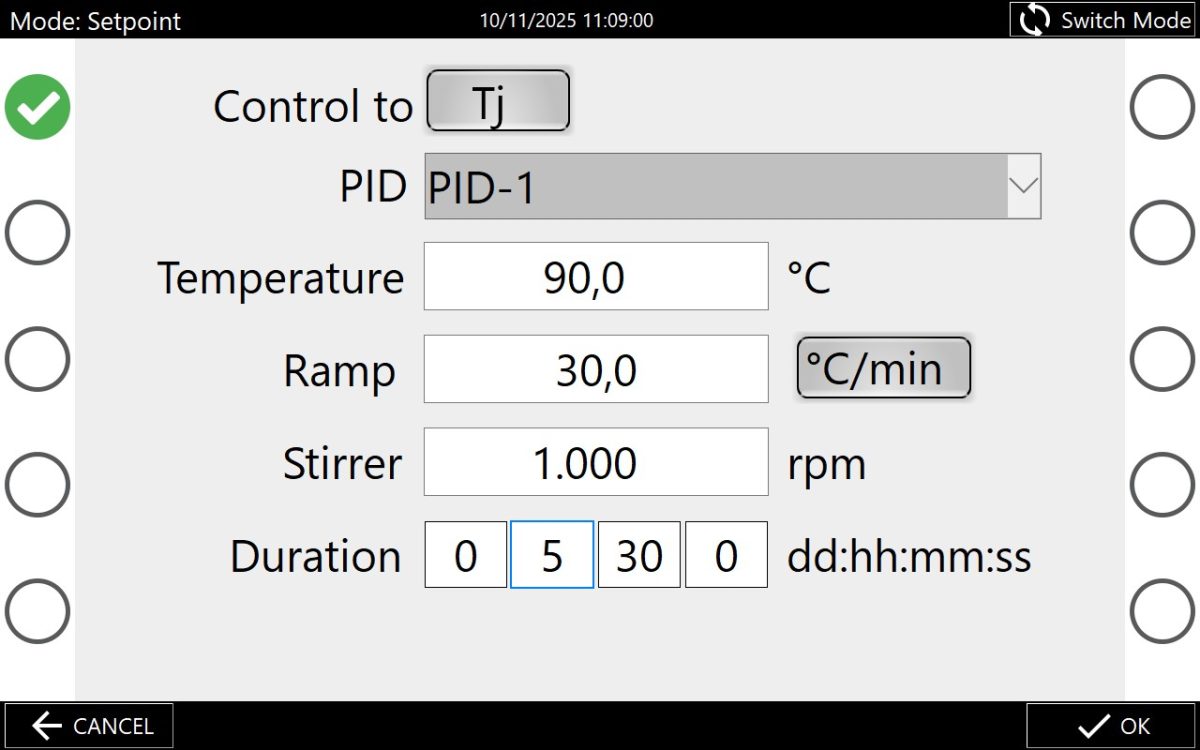

- Setpoint control of reaction parameters

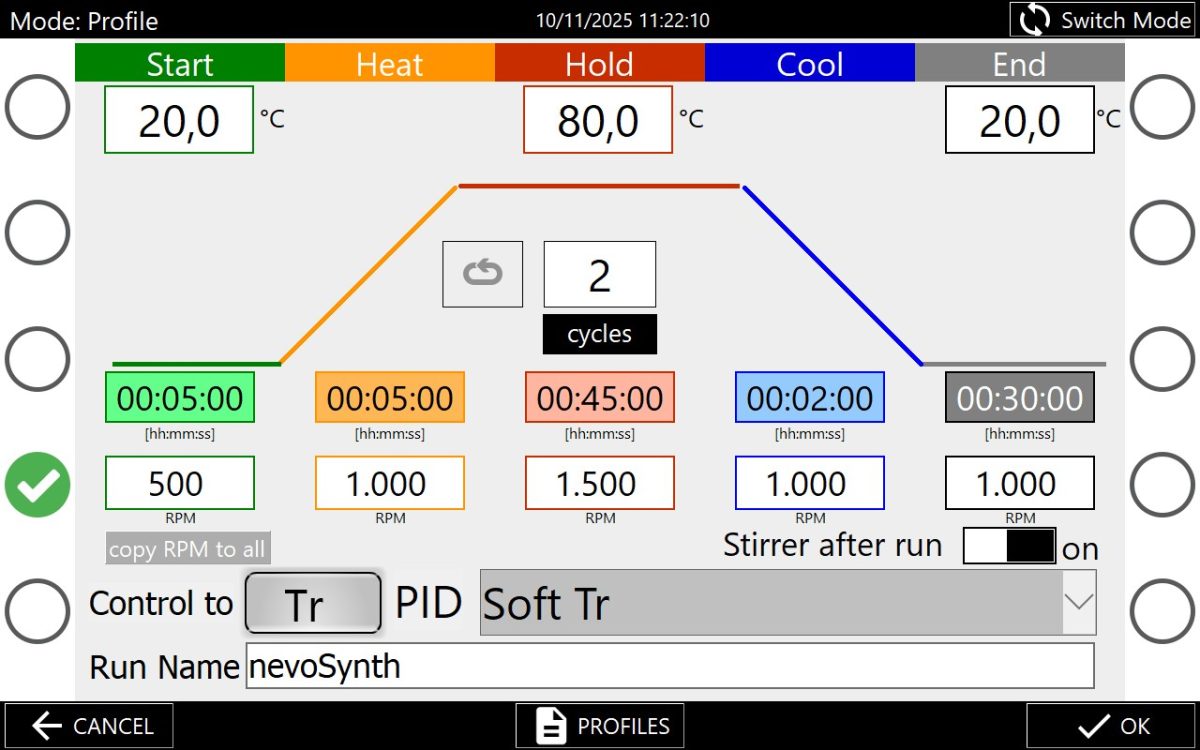

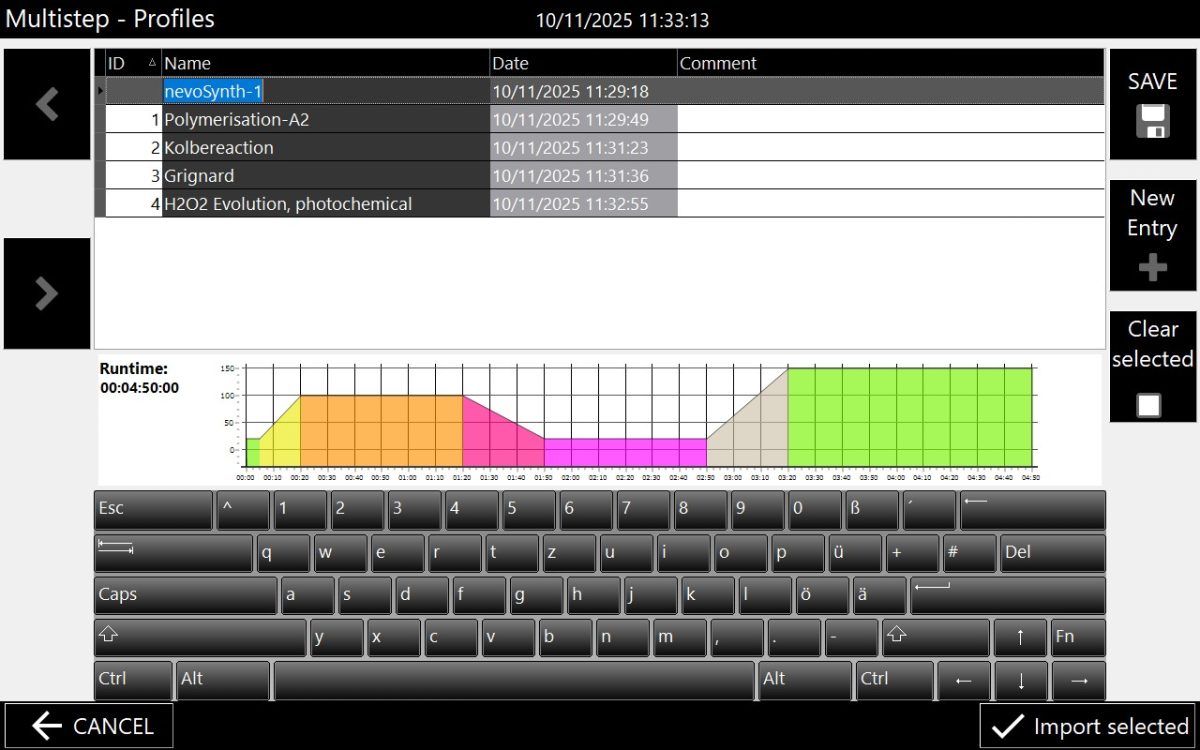

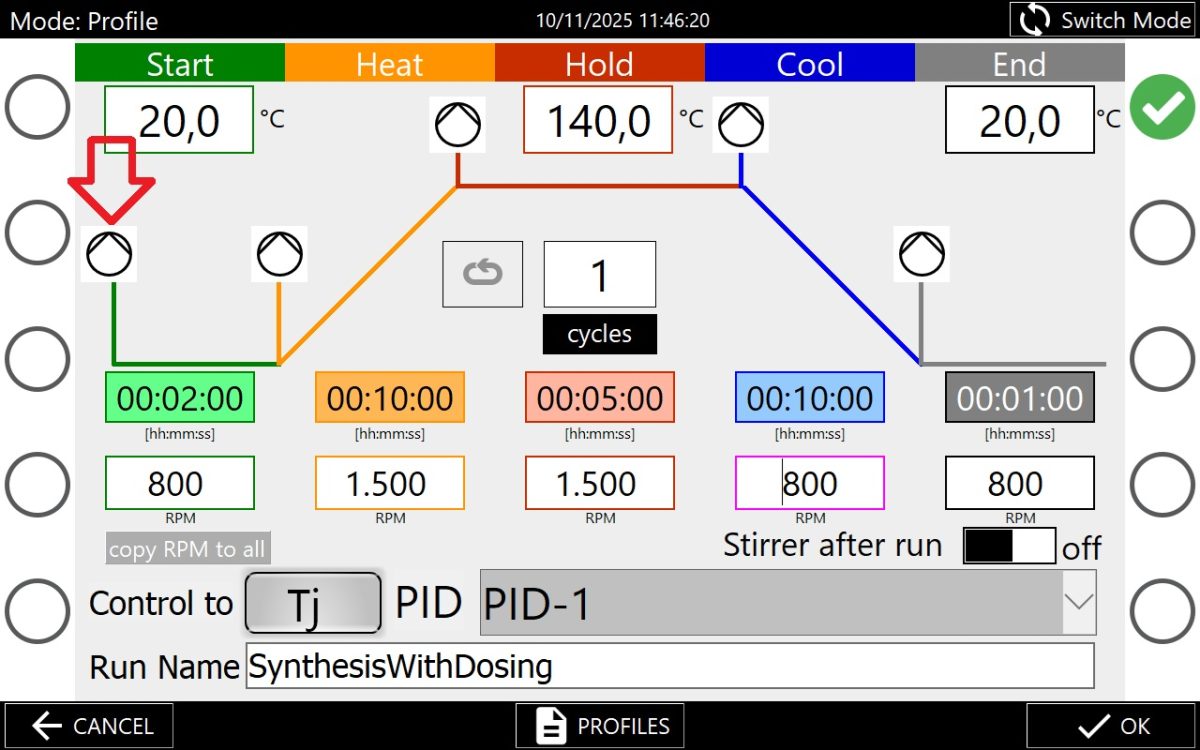

- Programmable reaction profile modes

- PI temperature control mode

- Monitoring & visualization of experiment progress and change of parameters

- Documentation and export of experimental data

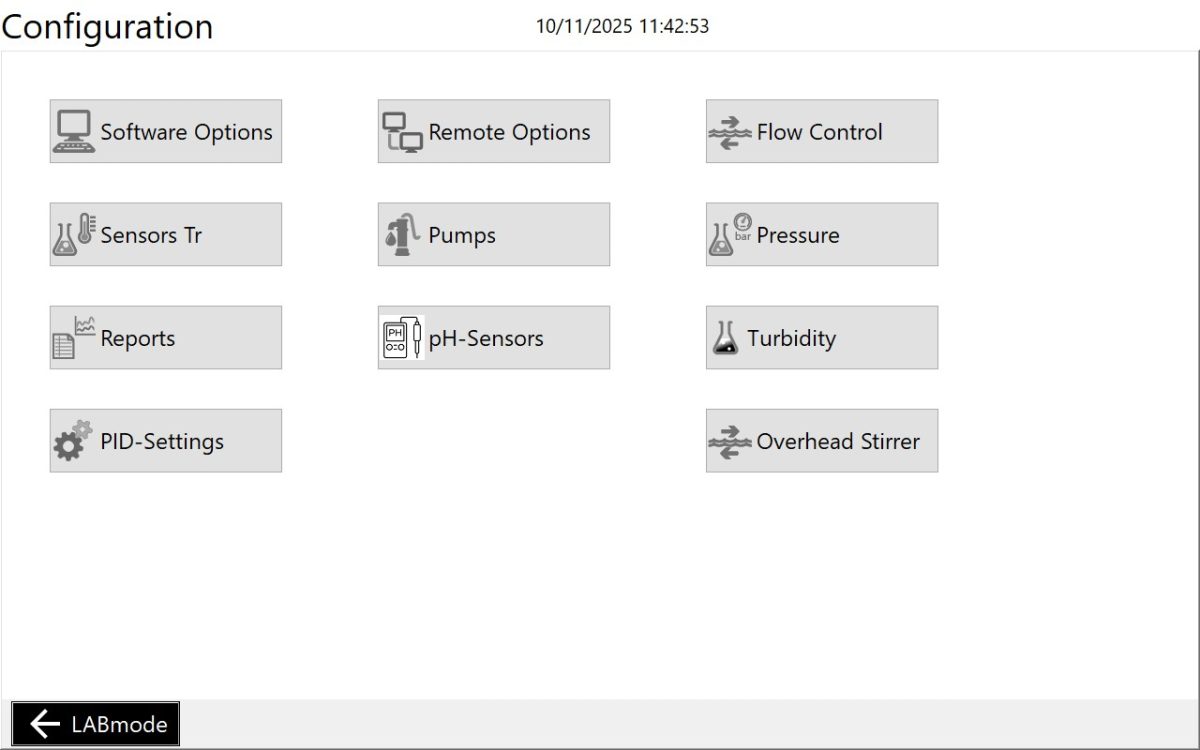

- Incorporation and operation of xelsius add-ons and sensors

- Remote control

- Free APIs for automation intergration

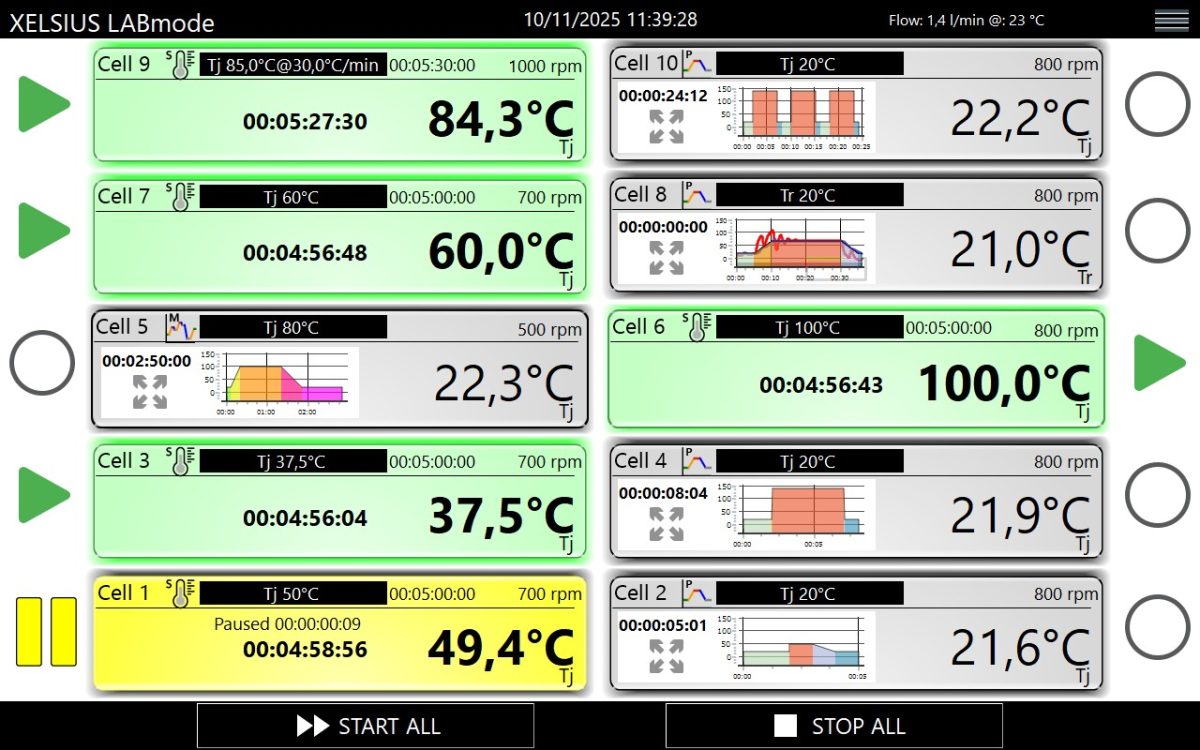

HOME SCREEN

Straight-forward operation from the beginning on.

The home screen represents the reactor layout from the top view, each tile stands for one of the 10 reactor positions:

Here experiments are started, paused, stopped individually or altogether.

For current experiments the run time or the reaction profile progress, as well as the heatingg jacket temperatures and reaction temperatures are live monitored.

SETPOINT CONTROL, REACTION PROFILE MODES & TEMPERATURE CONTROL

Setpoint control and setup of experiments are performed following three different reaction profile modes:

For these reaction profiles temperatures are controlled referring to the

• heating jacket temperature Tj (Reaction control equivalent to synthesis in tempered oil baths) or

• actual reaction temperature Tr inside the vessel or reactor, respectively.

For the later option an internal temperature sensor is employed, allowing a dynamic temperature regulation of the reaction medium via a PI controller.

PI temperature control can be optimized using varying presets, advanced users may define PI settings according to their needs.

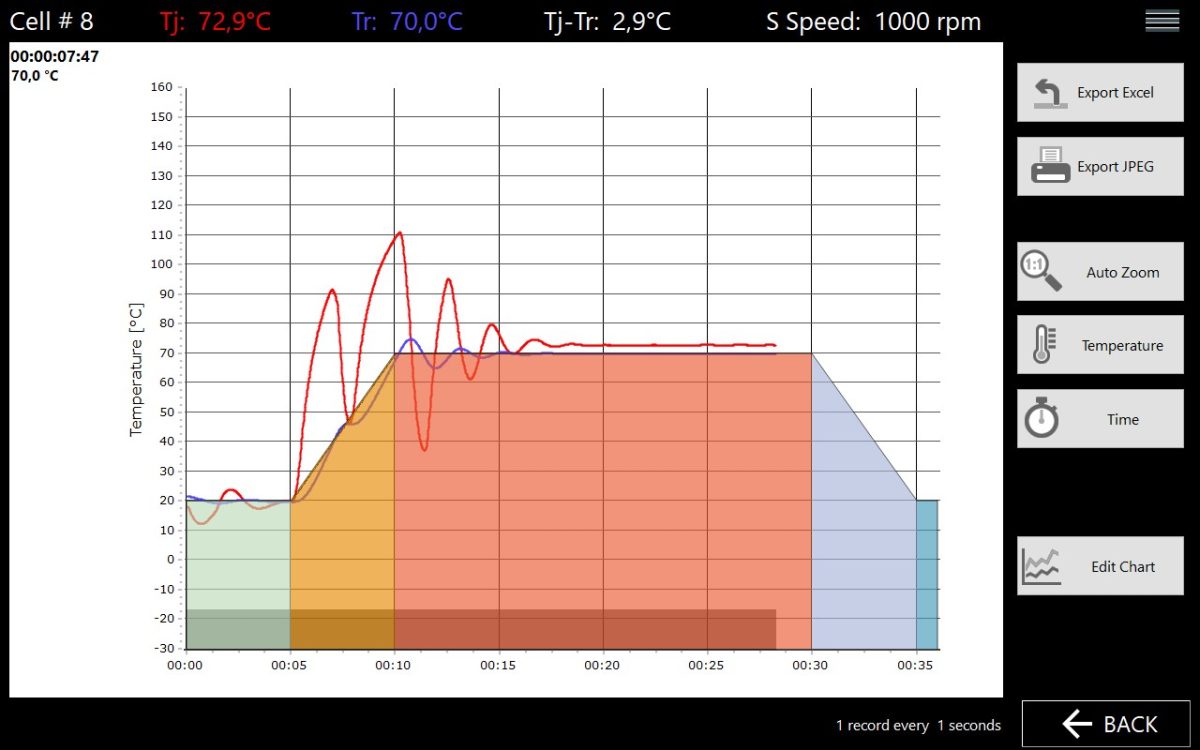

MONITORING

Ongoing experiments can be easily monitored as their progress and change of reaction parameters are visualized:

• The reaction profile is pictured within a T(t)-coordinate system

• A grey bar at the bottom indicates the experiments progress

• The change of monitored reaction parameters are represented as graphs.

Beside Tj & Tr (heating jacket temperature and reaction temperature) further parameters (e.g. pH, pressure) will be shown, if the according sensor is incooperated into the experimental setup and connected to the xelsius reactor.

DOCUMENTATION

• Aquisition of monitored process data on device internal storage

• Export of the experimental data is done in Excel and CSV format

• Transfer of data via USB port on the front of the xelsius device or via the following interfaces: Ethernet, REST-API and RS232.

EXTENDED FUNCTIONALITIES

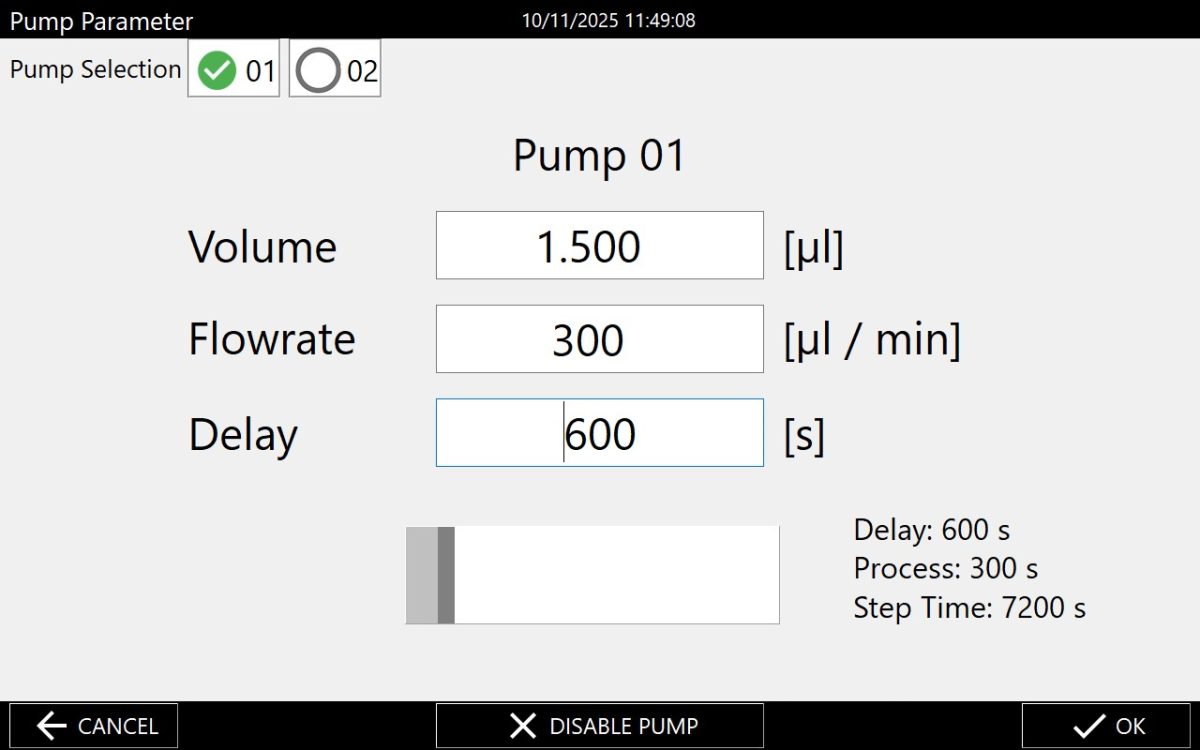

xelsius add-ons (e.g. dosing pump, overhead stirrer) and sensors (e.g. temperature probe, pH electrode) can be incorporated into the xelsius software environment and controlled:

For illustration the intergration of the dosing pump into the reaction profile modes is shown in the following:

FLEXIBLE OPERATION

● The xelsius control software can be remote controlled on external devices

● For integration into automation there are free APIs (Application Programming Interfaces)